DYNAMIC CHOICE E DYNAMIC DRAWINGS (dettagli)

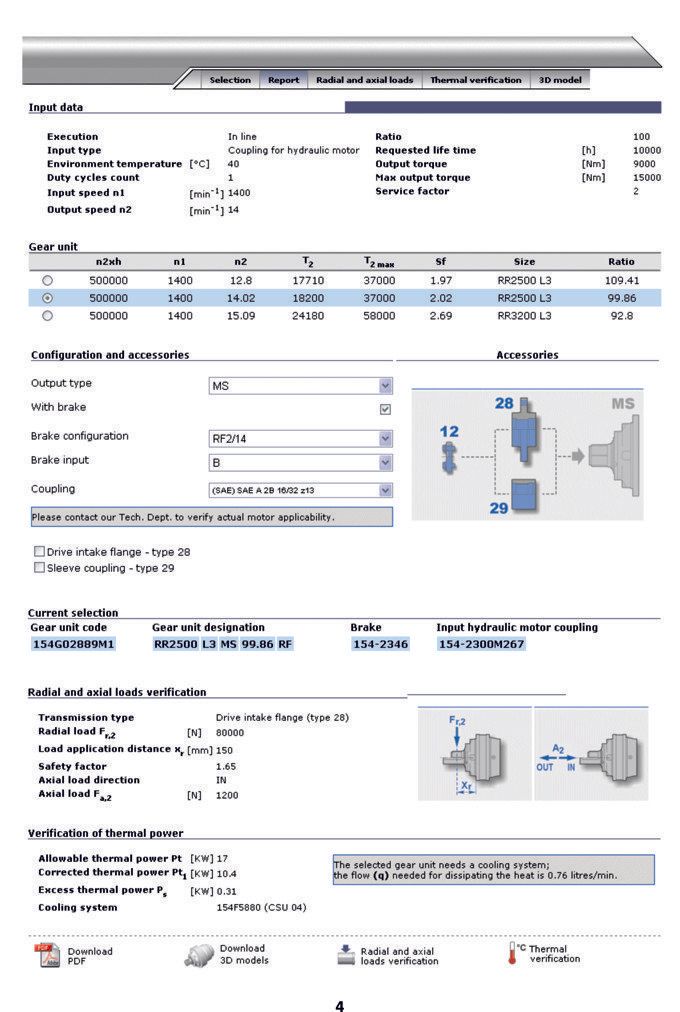

Description of the functions for configuring complex products such as speed reducers and gearmotors. Selection by product This procedure can be used when the user already knows the desired size and wishes to generate a designation, documentation and / or 2D / 3D CAD drawing. Guided in the selection, he is offered only the possible combinations with the help of some performance data that allow a first dimensional evaluation. The applicability of an electric motor or a flange for motor attachment (IEC or NEMA) is conditioned by the service factor attributed to the applicable power and displayed next to the available flange; configurations with service factor lower than 0.8 are not displayed (customizable limit). On the basis of the parameters entered, the program defines the selected series and size as a priority, taking as reference the nominal torque with fs = 1, it also searches the other product series for motors that have requirements close to those sought by listing those on the screen found. Having selected the one of interest, the user can proceed to the subsequent configuration by choosing the allowed options presented by the program, followed step by step by a dynamic help that proposes the topics contained in the catalog referring to the selection in progress. On request, it is possible to integrate the module for calculating and verifying the radial load on the output shaft based on the type of application required (gear, pinion for chain, etc.). It is necessary to point out that to make these selections we only use the basic performance data of the products, calculating the derived data each time, in this way we can manage very small archives that are easy to manage and update.

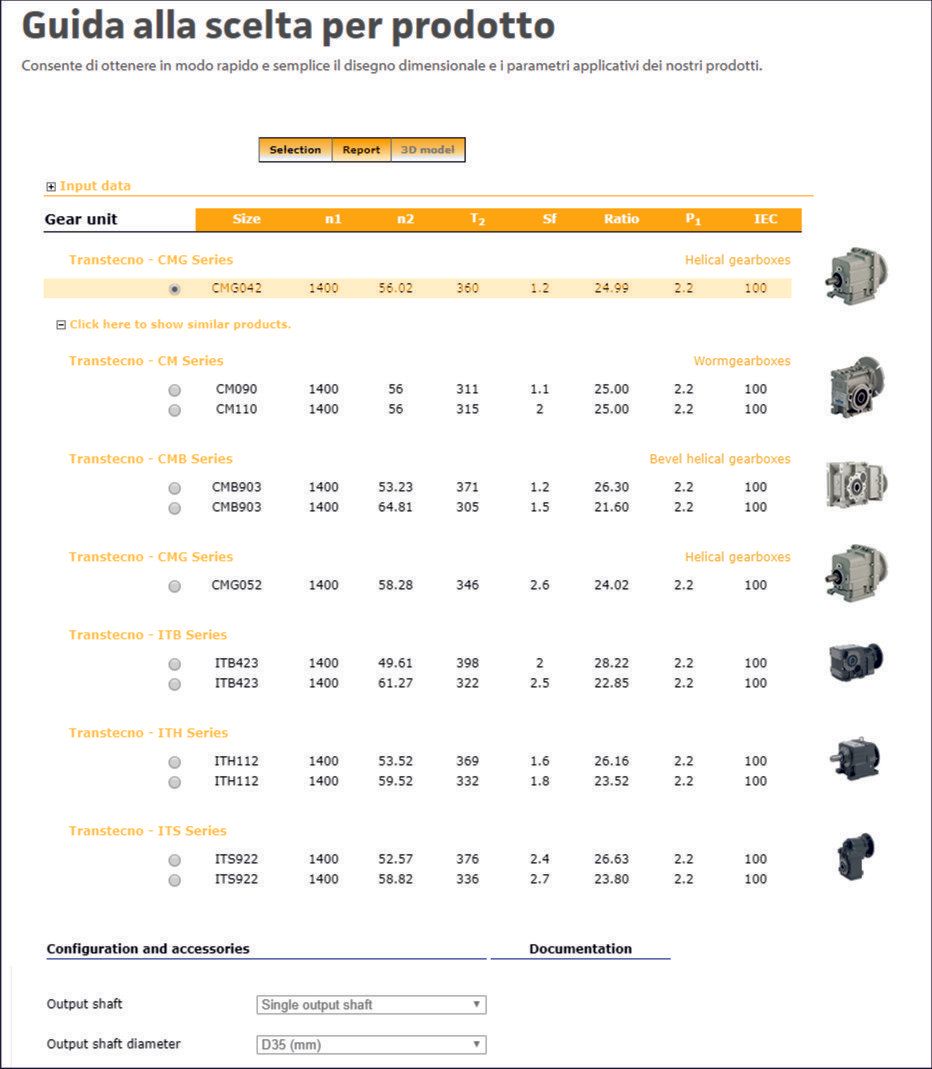

Selection by application data (kW, torque, rpm, fs) In the event that the user is not aware of the series and size of the gearbox but has the primary application data such as output rpm, torque or power, the program calculates and researches the optimal selections for each product series by proposing all available alternatives. There are filters to define the optimal selection based on the input speed and the required service factor. Since all the series with characteristics most similar to the first are displayed, the user can at his sole discretion proceed to select another series with characteristics of interest to him. A generic (or, if available) customized motor is configured in the gearmotors.